Self Build Design

As part of an ambitious self-build project in Nottingham, we designed, supplied and commissioned a heating and hot water system, allowing the customer to carry out the install.

The following schematics were supplied to the customer:

Hydraulic circuit

Pipe work plan

Electrical circuit (Heating and DHW)

3D Plant room layout

All major parts on the schematics were supplied by Eco Engineering direct to the customer and after installation the system was fully commissioned and checked to design by Eco Engineering.

The video below is an example of a plant room and the basic layout required to install all components and pipe work. As part of our design, we supply drawings with reference dimensions for your heating engineer or for self-builders to work to.

Plant room design for self builds

Solink PVT panels connected to a Ground Source Heat Pump (GSHP) and batteries

This highly insulated new build on the South coast has a heat loss of 7.9 kW with an outside air temperature of -4˚C. It uses Photovoltaic panels with an integrated solar thermal pipe system running at the back of the panels (PVT). The pipe work is then connected to a GSHP providing both heat and electricity to the property.

An innovative control system allows the PVT panels to switch on the GSHP whenever there is surplus electricity going to the grid. As the GSHP uses at least a 1:3 ratio, that is, 1 electricity in produces 3 x thermal energy out, the system gives 3 x the solar energy collected on the roof to heat a buffer tank, which can then be used for heating or hot water via a heat exchanger. Once the 800 litre buffer tank is to maximum temperature, any surplus from the PV system charges a 10 kW battery.

During summer months the GSHP is used to cool the house via the Mechanical Ventilation Heat Recovery (MVHR) system, the GSHP exhaust energy is used to heat the hot water tank if required.

The customer has signed up to an electricity tariff that buys energy back during peak times, therefore the building has negative running costs.

No need for expensive deep bore hole or slinky groundworks, the system uses the space on your roof

Quieter operation than an Air Source Heat Pump

Photovoltaic solar panels (PV), Air Source Heat Pump (ASHP) and Battery Storage

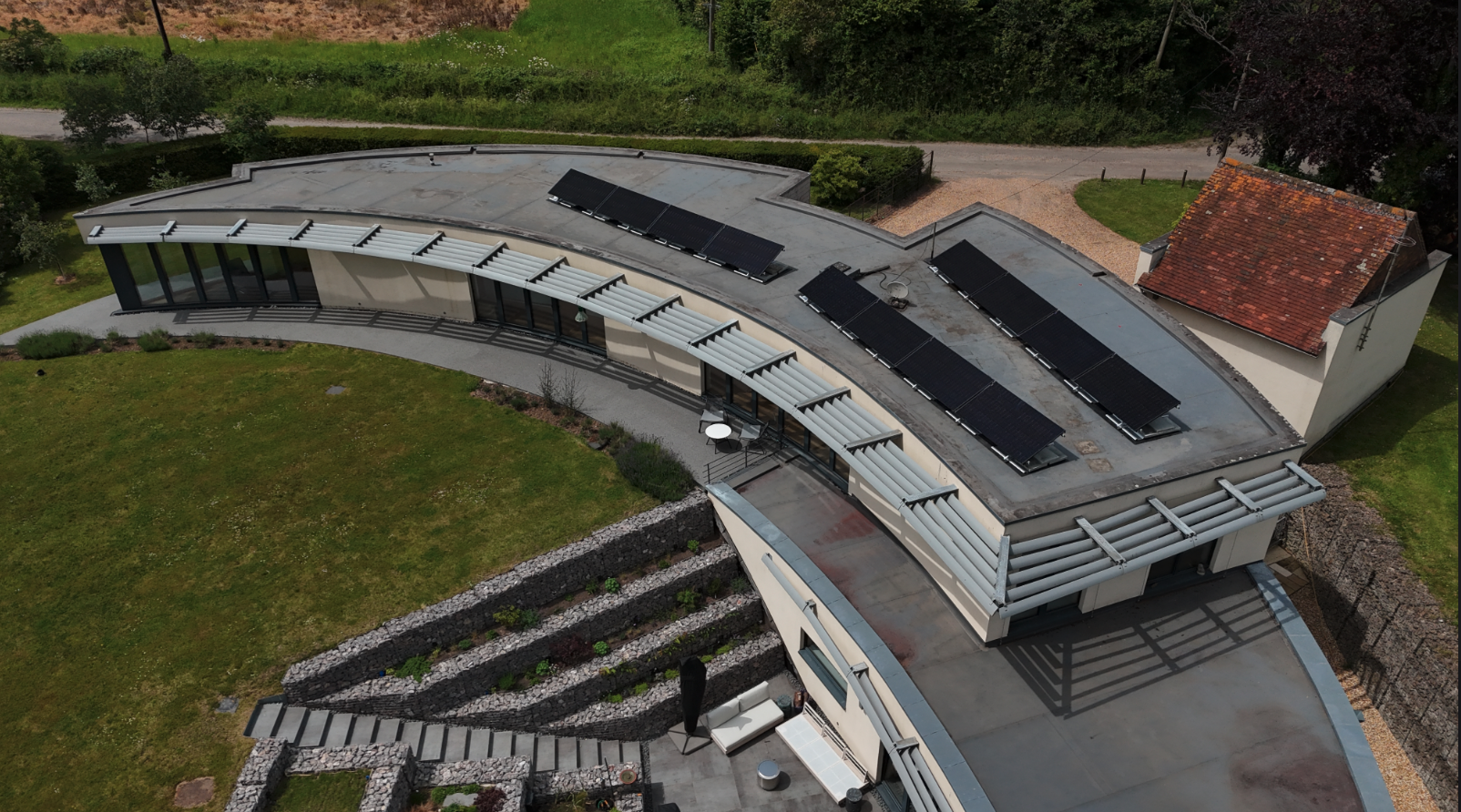

This barn near Bath was transformed into a comfortable off-grid, low energy home using highly effective insulation to reduce the heat demand to 12.7 kW including hot water.

An Ecoforest ASHP was the ideal choice to provide heat to the building as the underfloor heating (UFH) only needed a low temperature of 45˚C to fulfil the heat demand.

Two banks of Solar PV panels were installed onto the South and West facing roofs to maximise energy generation, these supply electricity to the ASHP. As the ASHP takes 1 x thermal energy in and generates 3 x thermal energies out, it produces 3 x the thermal energy into the thermal store than if the solar energy had been used elsewhere in the property during sunshine hours.

The system is connected to batteries allowing any excess solar energy to be stored and used later in the day or sold back to the grid via a smart electricity tariff.

The use of high quality insulation allowed us to specify a renewable energy solution with customer comfort at its core

Using solar PV energy to power the ASHP gives an additional boost to the electricity generated on the roof as the ASHP can generate 3 x the thermal energy into the hot water tank

Wood Chip Biomass System

A Fröling TX 199 kW Chip Boiler provides heat and hot water to this idyllic events venue near Chichester.

A purpose-built central biomass plant room and chip store generates heat for the main farm house and swimming pool, the wedding venue itself and guest accommodation.

Heat is fed into the buildings via a district heating system of underground pipe work.

The system is fully weather compensated, which can save up to 15% on annual fuel costs.

Wood chip is a good fuel choice if you own woodland and have access to handling equipment.

By chipping your own seasoned wood, bringing in a contract chipper, or buying wood chip in bulk it remains the cheapest biomass fuel for farms and other high energy users.

Wood Pellet

A Fröling PE1 20 kW fully automated pellet boiler provides heat and hot water to this domestic property.

A biomass boiler provides high temperature heat and is a good choice if the heat loss in a building is high, that is, if insulation levels cannot be improved and the heating is via a radiator system requiring high water temperatures.

The Fröling PE1 pellet boiler is one of the quietest on the market and therefore was suitable for installation into the utility room.

A wheelie bin acts as a pellet store, which needs filling approximately once a week in the winter. Bagged pellets are delivered on a pallet and stored ready for use.

Wood pellets can also be blown into a pellet store in bulk making it similar to an oil boiler system in that regular deliveries top up your fuel store.

A high efficiency Consolar thermal store was installed as the customer was keen to fit solar thermal panels in the future to reduce pellet usage during the summer months.

Quiet operation allowing installation into a utility room

High temperature heat for radiator systems and buildings with high heat loss

Photovoltaic solar panels (PV) and battery storage

This client approached us wanting to reduce reliance on fossil fuels.

They had already installed 2 x Air Source Heat Pumps (ASHP) and a backup oil boiler to heat and provide hot water to a large detached 6-Bedroom property, however they found their electricity bills were high.

Our solution was to install a PV and battery storage system sized to maximise self-consumption and ensure efficiency. The PV panels were installed onto an outbuilding and garage, being some 100 metres apart, which provided particular issues to overcome.

The system can be monitored via a smart phone.

During peak production times, the building generates 100% of the energy it needs from solar energy.

Annually, the self-sufficiency rate is 40 - 60% giving the client a substantial saving on annual fuel bills.

Solar Thermal

A solar thermal system was used on this project to reduce wood fuel usage.

The log/pellet boiler and solar thermal system feed heat into a 3000 litre thermal store, which is used to provide high temperature heating via a radiator system and hot water to this Cotswold stone house.

By timing the biomass boiler out during the day, solar gains can be maximised. The biomass boiler then tops up the store at the end of the day.

The solar thermal system has been installed for 5 years and has generated over 34,000 kW hours of solar energy saving the customer the equivalent of 10 tonnes of wood fuel.

Solar thermal systems require very little maintenance

Solar liquid should be checked every 5 years

If the system is sized correctly for the capacity of the thermal store, you will have a trouble-free system